Topics & News Release

2006/10/19

New development of the "T-11JAG-3S" internal grinding machine for fully automatic combined machining

-Two new products to be exhibited at the 23rd Japan International Machine Tool Fair -

Toyo Advanced Technologies Co., Ltd. (Head Office: Minami-ku, Hiroshima; President: Kenichi Yamamoto) will be exhibiting a total of three models at the 23rd Japan International Machine Tool Fair to be held at Tokyo Big Sight from November 1st to November 8th. These are two new products, the "T-11JAG-3S" internal grinding machine and the "T-182PG" vertical profile grinding machine, and the "T-182S" centerless vertical internal grinding machine which will be displayed for the first time at an exhibition in Japan.

-

-

The newly developed "T-11JAG-3S" is based on the "T-11JA"- a high performance, general-use internal grinding machine with broad market appeal. The T-11JAG-3S is equipped with a gantry loader, work inverter, and a turret (divider) which was developed independently by Toyo and can be equipped with four high-frequency wheelheads. (The exhibited machine has specifications with three wheelheads.) This machine is a combined machining unit which grinds multiple faces (such as internal faces and both end faces) with high-precision, using special purpose grinding wheels. It can operate in fully automatic, unmanned, continuous mode.

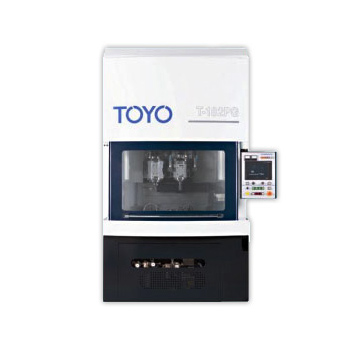

The other new product, the "T-182PG" was developed as a profile grinder for machining non-round parts such as cams. The unit is equipped with special-purpose wheelheads for rough grinding and finish grinding, and has greatly improved machining efficiency compared to conventional profile grinders. High-precision grinding with a profile precision of Φ5µm is achieved using a built-in servomotor for the work spindle and CNC employs the highly functional, interactive "TOYOMATIC-4000" which has an established reputation in internal grinding machines.

For both models, we expect to begin taking orders in earnest after the Japan International Machine Tool Fair in November.

At this Japan International Machine Tool Fair, Toyo's theme will be "Open the Grinding Future." In addition to the exhibited machines, our exhibit will introduce the overall concept of our vertical internal grinding machine series -- as one example of a future product line which pursues the possibilities of internal grinding machines.

Toyo's vertical internal grinding machine series, which first went on sale last year, already ranges from the compact chuck type "T-181C" to the mid-size centerless type "T-182S" and the large-size chuck type "T-183C". At the Fair, we also plan to disclose information on a large-size centerless type internal grinding machine which is expected to go on sale next spring, and three ultra-large vertical internal grinding machines which are currently under development (max. work outer diameter 2.5 m).

[List of machines to be exhibited at the 23rd Japan International Machine Tool Fair]

| Exhibited machines | New product | "T-11JAG-3S" internal grinding machine |

|---|---|---|

| New product | "T-182PG" vertical profile grinding machine | |

| - | "T-182S" vertical centerless internal grinding machine |

< New product > "T-11JAG-3S" internal grinding machine

The "T-11JAG-3S" is based on the "T-11JA" - a high performance, general-use model with broad market appeal - and is a fully automatic, combined grinding machine, which finishes multiple faces with high precision.

A gantry loader and work inverter are provided as standard equipment to enable one machine to handle work requiring machining from two directions, such as both ends. This enables an automatic cycle where the work is inverted, front to back, and achieves fully automatic, unmanned continuous operation. This greatly improves productivity.

Toyo has independently developed a special purpose turret which enables mounting of multiple wheelheads. The "T-11JAG-3S" has three high-frequency wheelheads mounted on a turret divided into 90 sections. (A maximum of four wheelheads can be mounted on the turret.) High-precision is achieved by machining each of the multiples faces (internal faces, taper faces, end faces etc.) with the optimal combination of wheelhead and grinding wheel. An NC work spindle swivel mechanism is available as an option, and this enables taper grinding with even higher precision.

< New product > "T-182PG" vertical profile grinding machine

-

The "T-182PG" is a vertical profile grinding machine for high-precision, high-efficiency grinding of non-round parts, and is equipped with two high-output, high-rigidity wheelheads.

The "T-182PG" is equipped with a high-output, high-rigidity wheelhead for rough grinding, and a high-speed, high-rigidity wheelhead for finish grinding. The different special-purpose grinding wheels are combined to achieve high-efficiency machining in rough grinding, and high-precision machining in finish grinding. Response has been enhanced by using a built-in servomotor for the C-axis (which is the work spindle), and profile precision has been increased by employing direct control of the C-axis, and high-level synchronous control with the X-axis which is both the cross-slide axis and forming axis. Precision stability has been improved by equipping the X-axis with a linear scale, and employing features such as a column cooling system and a dual-head structure. With these features, the system achieves high-precision machining with a profile precision of Φ5µm.

-

"TOYOMATIC-4000" - the established choice for CNC internal grinding machines - is used here for the first time in a vertical profile grinding machine. A new function for simulating X-axis movement has been newly added, and the system can even handle external grinding of non-round shapes.

< New product > "T-182S" vertical centerless internal grinding machine

-

The "T-182S", whose beautiful design and vertical centerless functionality won acclaim at the Chicago Show held in September of this year, will also be exhibited at the Japan International Machine Tool Fair.

The "T-182S" is Japan's first vertical centerless internal grinding machine, and is a machine suitable for machining of mid-size bearings with outer diameters up to 240 mm. Machine width is less than half that of conventional horizontal internal grinding machines, so production lines can be shortened.

-