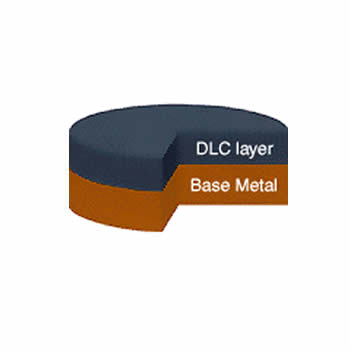

DLC

The coating by which taigyouchakusei has a high friction coefficient low

By utilizing plasma energy of PVD method , DLC film is formed by resolving hidro-carbon gas. DLC coating whose characteristics features very hard but thin film consists of Carbon atom as Diamond dose .

Features

Excellent hardness, Hv = from 3000 to 5000

Low treatment temperature (200°C or less), virtually eliminating thermal deformation

Very smooth surface and the lowest coefficient of friction

Low adhesion to the material used in powder compress molding

High adhere resistance for soft metals

Typical Applications

Many kinds of powder molds

Parts for semiconductor manufacturing

Molds and cutting tools for Aluminum , Copper and Brass

Parts requiring adhere resistance

Medical equipment such as stents

Application coating films with strengthened characteristics by changing composition of DLC

| Product | Coating Hardness |

Standard Thickness | Features | Main Applications |

|---|---|---|---|---|

| DLC | Hv3,000 -5,000 |

1±0.2µm | A general-purpose hard coating that provides an excellent balance of hardness and adhesion resistance •Friction properties: 0.1 •Heat resistance: 400℃ |

[ Soft metal forming ] •Lead frame bending dies [ Machinery, automotive components ] •Engine components [ Medical use ] •Stents, catheters |