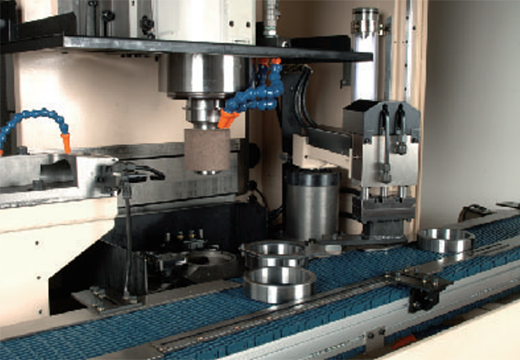

Vertical Grinder (Centerless Type)

Lineup with a maximum grinding diameter of up to 650 mm.

Workpiece support with 2-shoe magnet.

Ideal for grinding of bearings and other components that require concentricity between the external and inner surfaces.

TVG-15S

Structure pursuing increased machining efficiency

The inertia mass of the X-axis is minimized for sufficient TAC (constant adaptive grinding power control) performance. This contributes to increased machining efficiency.

Space saving

The X-axis is situated above the Z-axis to minimize the machine width. This will help you to save space at your plant or shorten lines.

T-182S,T-183S,T-184S

Unmanned and Labor-Saving Operations

There is a wide variety of optional equipment available, including a conveyor and swing loader which are highly versatile. This also helps achieve longer unmanned operations in high-variety small-lot production.

Main Specifications |

TVG-15S | T-182S | T-183S | T-184S | |

|---|---|---|---|---|---|

| Workpiece support method | two-shoe magnet | two-shoe magnet | two-shoe magnet | two-shoe magnet | |

| Loadable workpiece O.D. | φmm | 40~130 | 90~240 | 110~420 | 300~650 |

| Grindable workpiece width | mm | 10~60 | 20~90 | ~250 | ~300 |

| Dimensions (Width×Depth×Height) |

mm | 1,180×2,300×2,550 | 1,470×2,610×2,880 | 2,790×3,450×3,250 | 3,115×3,650×4,050 |