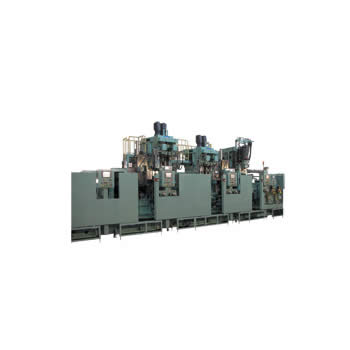

T-BF

Designed for cylinder block machining, this composite machine combines boring and honing capabilities in a single system.

- Cost Reduction

- Makes it possible to concentrate processes that generate chips in one location and reduce costs associated with equipment such as coolant tank. Employing water-soluble coolant for honing processes also reduces costs associated with washing equipment.

- Precision Boring

- Maintain bore diameter of "1 rank" precision within 12µm tolerances.

- Highly efficient machining

- The bore finisher can complete 4-cyl.block with a cycle time of 0.8 min.

- Compact Design

- The overall length of the machine is shortened to 10 m. This represents a 37% space reduction compared with conventional machines.

- Improved Work Environment

- Using-water-soluble coolant for honing process results in a much improved work environment compared with systems using straight oil coolant.

- Mixed Production

- Cylinder blocks of two different diameters can be handled in random order on the same line within the same cycle time.

Main Specifications |

T-BF |

|---|---|

| Overall Length | 10m |

| Overall width | 3.8m |

| Machining Work Type | Mixed Production of 2 Bore Diameters |

| Transfer Method | Lift and Carry |

T-BF Application |

||

|---|---|---|

|

φ74X133mm |

Size variation | 5.0 μm |

| Roundness | 0.7~4.20 μm | |

| Cylindricity | 5.7 μm | |

| Surface roughness | 1.88~2.71μmRz 0.38~0.83μmRpk |

|

| Cycle time | 0.8min./pc. | |