Topics & News Release

2024/10/18

Toyo Develops New Models of Its Horizontal Internal Grinding Machines and Gear Grinding Machines

― Two grinding machines that support automation and labor saving will be exhibited at JIMTOF2024 ―

Toyo Advanced Technologies Co., Ltd. (head office: Minami-ku, Hiroshima-shi, Hiroshima, President: Yuichi Hayano, hereinafter the "Company")) announces that it has developed new models of THG-35C, a horizontal internal grinding machine and TGG-26-2W-HS, a gear grinding machine. It will exhibit them at JIMTOF2024, or the 32nd Japan International Machine Tool Fair, to be held from Tuesday November 5 through Sunday November 10, 2024.

At this exhibition, the Company will offer a range of solutions to address task that the manufacturing industry is facing such as the realization of high-level precision and productivity, improvement of automation, labor saving, workability and operability, as well as actions for decarbonization.

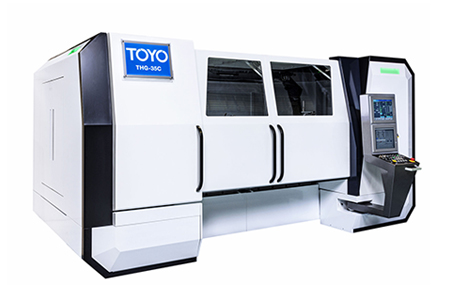

【Internal Grinding Machine:THG-35C】

The THG-35C is a chuck-type horizontal internal grinding machine suitable for long workpieces such as machine tool spindles. Building on the current model (T-1254N), the Company has adopted new materials to realize stable machining while simultaneously incorporating the automation of centering work. Through these initiatives, it will propose high precision machining that can be implemented with less dependence on skilled work.

<Main features of THG-35C>

① Minimize temperature changes in machining, thereby achieving stable processing.

The full-closed control is adopted on the X-axis and Z-axis in the newly developed cross-table and a mineral cast was

adopted in the bed. High-level vibration damping performances and superb thermal stability realize high-precision and stable

machining.

② Automates an issue of centering work through the capability of machining long workpieces.

The eccentricity of the outer circumference and end surface of a workpiece is measured and the position of the chuck and

workrest is automatically adjusted.

③ A new design features improved workability and operability.

Workability is improved through enhanced accessibility to the inside of a machine. Operability is also improved through the

incorporation of two screen-based control panels and with the expansion of the movable range.

At the JIMTOF2024, the Company will perform a demonstration of automatic centering and tapered machining shaft.

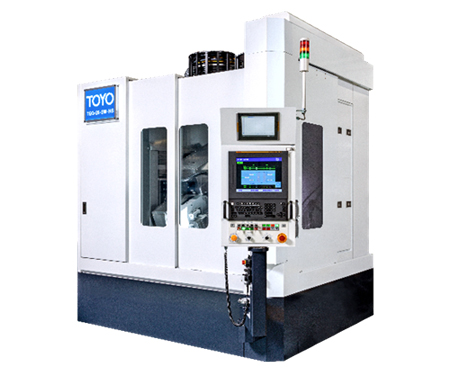

【Gear Grinding Machine:TGG-26-2W-HS】

The TGG-26-2W-HS is a gear grinding machine that enables high-efficient machining of small-diameter gears and shafted gears. By incorporating automation and labor-saving technologies such as the automatic replacement of grinding wheels using ATC device and the one-touch replacement of chucks, the Company will propose the maximization of throughput in gear grinding.

<Main features of TGG-26-2W-HS>

① Realizes the high-efficient machining of small-diameter gears with a high-speed wheelhead and a high-speed workhead.

A wheelhead with a maximum rotational speed of 13,500 min-1 and a workhead with 6,000min-1 respectively have been

developed by adopting a small-diameter grinding wheel. They ensure high-efficient machining with sufficient peripheral

speed secured.

② Continuous operation for long hours through automatic grinding wheel replacement

Equipped with ATC device, automatic replacement can be made when the wear of the grinding wheel occurs.

③ Labor-saving in changeover operations

One-touch replacement without using tools is possible for the chuck and tailstock that keep a workpiece. In addition, the

position of the tooth surface indexing device can be adjusted automatically. Changeover time has been reduced significantly.

At JIMTOF2024, the Company will display the product at the gear grinding line, which is linked by a robot to the TVG-20C-2S, a vertical complex grinding machine. It will perform a demonstration, showing grinding of the inner diameter and end face of a gear with the TVG-20C-2S and grind the tooth surface the Company will display the product at the gear grinding line, which is linked by a robot to the TVG-20C-2S, a vertical complex grinding machine. It will perform a demonstration, showing grinding of the inner diameter and end face of a gear with the TVG-20C-2S and grind the tooth surface with the TGG-26-2W-HS.

References

THG-35C |

|

■Main specifications of the exhibited model |

|

Floor space (Width × Depth × Height) |

: 4,250×2,410×2,100mm |

Maximum grindable hole diameter |

: Φ350mm |

Maximum grindable length |

: 350mm |

|

|

TGG-26-2W-HS |

|

■Main specifications of the exhibited model |

|

Floor space (Width × Depth × Height) |

: 2,440×2,050×2,850mm |

Maximum grindable outside diameter |

: Φ260mm |

Maximum grindable width |

: 220mm |

|

|