Topics & News Release

2016/10/19

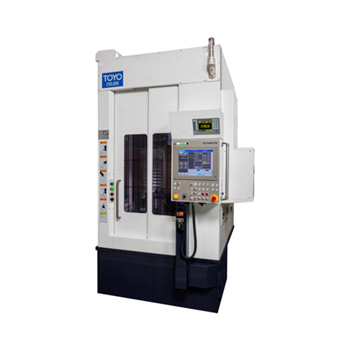

Announcing the Development of the Shoe Centerless-Type Compact TVG-20S Vertical Composite Grinding Machine

- Equipped with the newly developed automatic shoe-offset switch that provides grinding of inner and outer diameters using only one chuck -

Toyo Advanced Technologies Co., Ltd. (Head office: Minami-ku, Hiroshima, President: Nobuhiko Narisawa) has newly developed the shoe centerless-type TVG-20S grinding machine based on the TVG-20C (a chucking type compact vertical composite grinding machine) that will serve as an addition to the line-up of the TVG series of vertical composite grinding machines which use the main spindle travel method. The company has already started full-scale sales of the new model.

This new grinder model is perfect for machining of small-diameter thin-walled workpieces such as bearings, and is equipped with a 2-shoe & magnetic chuck. While compact in size, the new model has a rich variety of options including an automatic tool changer (ATC), turret device, and patented automatic shoe offset switch capable of grinding both inner and outer diameters. It can not only perform one-chuck composite grinding of inner and outer diameters but also mass production, high-variety small-lot production, and other variable-type/quantity production.

-

This newly developed TVG-20S is a compact vertical composite grinding machine capable of shoe centerless grinding of cylindrical workpieces up to an outer diameter of φ170 mm and inner diameter of φ162 mm. It utilizes an independent cutting spindle (X-axis) and table spindle (Z-axis), with the main spindle situated on the X-axis, for a unique movable main spindle system that serves to reduce Z-axis torsion caused by machining loads and provide high-precision machining thanks to a low center of gravity and high rigidity.

When machining small-diameter thin-walled cylindrical workpieces, the suction force of a magnetic chuck is not sufficient to retain such workpieces making it necessary to perform shoe centerless grinding using our 2-shoe & magnetic chuck. The shoes must be rearranged when the machining surface changes because the appropriate positions of the shoes vary depending on whether you are grinding the inner or outer diameter surface. However, our new model does not require rearranging of the shoes thanks to the automatic shoe offset switch we developed that automatically moves the shoes to the appropriate positions. Use of the turret device (equipped with two wheel heads for inner and outer diameters) and ATC (six pieces) allows you to perform composite grinding of inner and outer diameter surfaces using the same machine without having to perform setup changes, making it perfect for use in trial and high-variety small-lot production. You can also use this new model in combination with robots for creating unmanned production lines making it the perfect equipment for any production line. We can provide you with a machine having the optimal specifications to match your exact needs and type of production.

-

In addition to the new release of this TVG-20S, we have also added a mid-size shoe centerless-type machine (TVG-35S) to the TVG series. The TVG series has been fully enhanced with the addition of these shoe centerless-type grinders to this series of machines which use the main spindle travel method.

This new model will also be on display at the 28th Japan International Machine Tool Fair (JIMTOF 2016) that opens at the Tokyo Big Sight from Nov. 17 (Thurs.).

TVG-20S Basic Specifications

Installation dimensions (Width x Depth x Height): |

1,300 x 2,450 x 2,600 mm |

Max. grindable workpiece outer diameter: |

φ170 mm |

Max. grindable workpiece inner diameter: |

φ162 mm |

Max. grindable workpiece width: |

150 mm |